Introduction

At Draco Logistics, we pride ourselves on redefining industry standards. Our commitment to excellence extends to every aspect of warehouse logistics, where precision, efficiency, and innovation converge to create a seamless and optimized supply chain. As your trusted partner, we are here to guide you through the fundamental principles and intricacies of warehouse logistics.

The Importance of Warehouse Logistics

Warehouse logistics is the heartbeat of an effective supply chain. It involves the strategic planning, organization, and optimization of the movement of goods within a warehouse facility. Efficient warehouse logistics ensures that products are not only stored securely but also managed, picked, packed, and shipped with the utmost precision. In a global marketplace where customer expectations are ever-evolving, the importance of streamlined warehouse logistics cannot be overstated.

In this guide, Draco Logistics invites you to delve into the essentials of warehouse logistics. From understanding key concepts to exploring advanced technologies and best practices, we aim to empower you with the knowledge needed to navigate the complexities of warehouse logistics successfully. Join us on this journey as we uncover everything you need to know to enhance the efficiency and effectiveness of your warehouse operations.

What Is Warehouse Logistics?

Warehouse logistics—often referred to as “warehouse management” or “logistics management”—is a critical component of supply chain management that focuses on the efficient planning, organizing, and controlling of the storage and movement of goods within a warehouse facility. It encompasses a range of activities aimed at optimizing the flow of products, from their arrival at the warehouse to their departure for distribution or fulfillment.

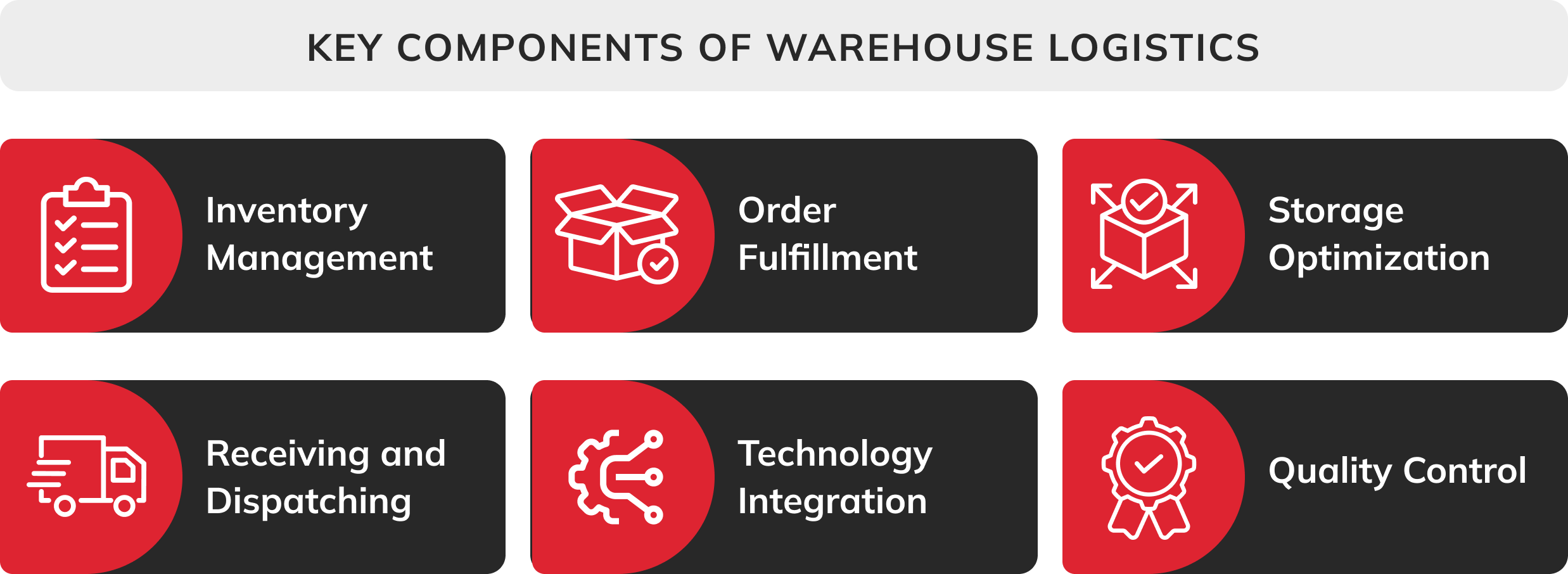

Key Components of Warehouse Logistics

Inventory Management: Warehouse logistics involves systematic inventory tracking to ensure optimal stock levels, prevent stock-outs or overstock situations, and enhance overall inventory accuracy.

Order Fulfillment: Efficient order fulfillment is a core aspect, encompassing processes such as order picking, packing, and shipping to ensure accurate and timely delivery to customers or distribution centers.

Storage Optimization: Warehouse logistics includes strategic storage planning to maximize space utilization, improve accessibility, and facilitate efficient movement of goods within the warehouse.

Receiving and Dispatching: The process begins with the receiving of goods into the warehouse and extends to the dispatching of products for distribution or shipment, emphasizing accuracy and timeliness.

Technology Integration: Warehouse logistics leverages advanced technologies such as Warehouse Management Systems (WMS), RFID, and automation to enhance efficiency, accuracy, and overall operational effectiveness.

Quality Control: Ensuring the quality of stored products through rigorous quality control measures is an integral part of warehouse logistics, preventing defects or damages to goods.

The Role of Warehouse Logistics in Supply Chain

Warehouse logistics is the backbone of an effective supply chain, seamlessly coordinating warehouse activities to precisely and efficiently store, manage, and deliver products. As a critical component in the supply chain, robust warehouse logistics contributes to:

Timely Order Fulfillment: By ensuring efficient order processing and prompt picking and packing of orders, warehouse logistics enables quick delivery of products, leading to improved customer satisfaction.

Cost Efficiency: Optimizing storage density, inventory tracking, resource planning, and material flows results in reduced operational and logistics expenses.

Responsiveness: Streamlining put-away, replenishment, and order preparation activities equips supply chains to swiftly adapt to changes in market demands or customer requirements.

Warehouse Design and Layout

The design and layout of a warehouse play a pivotal role in shaping its operational efficiency and overall effectiveness. A smart warehouse design goes beyond aesthetics; it is a strategic blueprint that directly influences the flow of goods and the productivity of warehouse logistics. Here’s why warehouse design and layout are crucial components in optimizing processes:

Space Utilization: A well-designed warehouse maximizes space utilization. Strategic placement of storage racks, shelving units, and workstations ensures that every square foot is utilized efficiently, minimizing wasted space and accommodating varying inventory needs.

Workflow Optimization: Warehouse design is instrumental in optimizing workflows. An efficient layout minimizes the travel distance for goods, streamlining processes such as picking, packing, and shipping. This not only enhances speed but also reduces the likelihood of errors in the movement of products.

Accessibility and Visibility: The layout of a warehouse determines the accessibility and visibility of products. Properly organized storage areas and clear pathways make it easier for warehouse staff to locate and retrieve items, contributing to faster order fulfillment and improved overall operational visibility.

Zoning for Efficiency: Zoning specific areas for different functions, such as receiving, storage, and shipping, facilitates a smooth and organized workflow. A well-designed warehouse is segmented logically, ensuring that each zone is optimized for its intended purpose.

Adaptability to Change: The design and layout should be adaptable to changes in inventory volume, product types, and operational needs. Flexibility in design allows for easy modification and expansion as the business evolves, ensuring the warehouse remains aligned with changing requirements.

Integration of Technology: Modern warehouse design incorporates the integration of technology, such as RFID systems, automated material handling, and Warehouse Management Systems (WMS). This integration enhances overall efficiency, accuracy, and real-time monitoring of warehouse processes.

Safety and Compliance: A well-designed warehouse prioritizes safety and compliance with industry regulations. Proper aisle widths, designated storage areas, and safety protocols contribute to a secure working environment and adherence to legal standards.

Cost Efficiency: Efficient warehouse design directly impacts cost efficiency. By reducing unnecessary movement, minimizing errors, and maximizing storage capacity, a well-designed warehouse contributes to lower operational costs and improved profitability.

Inventory Management in Warehouse Logistics

Inventory management is the heartbeat of warehouse logistics, and its efficient execution is central to the success of supply chain operations. At Draco Logistics, we recognize the critical role that accurate and organized inventories play in ensuring seamless warehouse logistics. Here’s an insight into the aspects of inventory management within our warehouses:

Real-Time Tracking with Technology: Draco Logistics leverages state-of-the-art technology, including Warehouse Management Systems (WMS) and RFID systems, for real-time tracking of inventory. This technology enables us to monitor the movement and status of each product within the warehouse, providing up-to-the-minute visibility.

Accurate Receiving and Put-Away Processes: The journey of a product begins with accurate receiving processes. Draco Logistics places a strong emphasis on meticulous checks and verifications during the receiving phase. Our organized putaway processes ensure that products are assigned to their designated storage locations accurately.

Demand Forecasting and Order Planning: Successful inventory management involves anticipating demand trends. Draco Logistics employs advanced analytics and demand forecasting techniques to plan orders effectively, preventing overstock or stockout situations and optimizing inventory levels.

Cycle Counting and Regular Audits: To maintain accuracy, Draco Logistics implements regular cycle counting and audits. This proactive approach allows us to identify discrepancies, correct errors promptly, and uphold the integrity of the inventory records.

Strategic Placement for Efficiency: The placement of products within the warehouse is strategically planned to facilitate efficient picking and packing. Frequently accessed items are positioned for quick retrieval, contributing to faster order fulfillment and reduced handling times.

Serialized Tracking for Traceability: Serialized tracking is employed for traceability, ensuring that each product can be traced back to its origin. This is especially crucial for industries with stringent regulatory requirements or those dealing with products that have expiration dates.

Minimizing Shrinkage and Loss: Draco Logistics prioritizes measures to minimize shrinkage and loss. This includes implementing security measures, conducting thorough inspections, and fostering a culture of responsibility among warehouse staff.

Continuous Improvement Practices: Inventory management is an evolving process. Draco Logistics is committed to continuous improvement, regularly reviewing and enhancing inventory management practices to adapt to changing market dynamics and emerging industry trends.

Our warehouses are not just storage spaces; they are hubs where every product is meticulously managed, ensuring that your inventory is a strategic asset that contributes to the success of your supply chain.

Order Fulfillment Strategies

Efficient order fulfillment is the cornerstone of successful warehouse logistics, ensuring that products are picked, packed, and shipped with precision to meet customer expectations. At Draco Logistics, we employ a range of strategies to optimize order fulfillment and guarantee accurate deliveries:

Pick-and-Pack Optimization: Draco Logistics focuses on optimizing the pick-and-pack process. This includes strategically organizing products within the warehouse for efficient picking, utilizing technology such as picktolight systems, and employing streamlined packing procedures to minimize errors.

Batch and Wave Picking: To enhance efficiency, Draco Logistics employs batch and wave picking strategies. Batch picking allows multiple orders to be picked simultaneously, while wave picking organizes orders into waves, optimizing the sequencing of picking tasks for faster fulfillment.

Technology-Driven Solutions: Integration of technology, including Warehouse Management Systems (WMS) and barcode scanning, enhances order fulfillment accuracy. real-time updates and automated tracking contribute to precise order processing and minimize the risk of errors.

Cross-Docking for Rapid Transfers: Cross-docking is employed for time-sensitive products. This strategy involves transferring goods directly from receiving to outbound shipping, minimizing the need for storage. This reduces handling times and accelerates order fulfillment.

Dynamic Slotting: Draco Logistics implements dynamic slotting strategies to adapt to changing product demand. Frequently ordered items are strategically placed for quick access, minimizing travel time and ensuring rapid fulfillment of high-demand products.

Multi-Channel Fulfillment: With the rise of multi-channel retailing, Draco Logistics adopts strategies for efficient multi-channel fulfillment. This ensures that orders from various channels, including ecommerce platforms and brick-and-mortar stores, are processed seamlessly.

Continuous Training and Quality Control: Order fulfillment excellence is maintained through continuous training programs and stringent quality control measures. Warehouse staff is trained to follow standardized procedures, and regular quality audits are conducted to uphold the accuracy of order processing.

Last-Mile Delivery Optimization: Draco Logistics recognizes the importance of the last mile in order fulfillment. Strategies such as route optimization, real-time tracking, and strategic placement of distribution centers contribute to efficient and on-time last-mile deliveries.

Draco Logistics employs a holistic approach to order fulfillment, combining technological innovation, strategic planning, and a commitment to quality. Our order fulfillment strategies are designed to not only meet but exceed customer expectations, ensuring that every order is processed accurately and delivered with the speed and precision that define our commitment to excellence in warehouse logistics.

Technology Integration in Warehouse Operations

Technology is a driving force that revolutionizes warehouse logistics, enhancing efficiency, accuracy, and overall operational performance. At Draco, we prioritize the seamless integration of technology to elevate every aspect of warehouse operations. Here’s how technology plays a pivotal role in optimizing our warehouse logistics:

Warehouse Management Systems (WMS)

Draco Logistics leverages advanced WMS to orchestrate and streamline various warehouse processes. WMS provides real-time visibility into inventory, order status, and overall warehouse performance, allowing for informed decision-making.

RFID and Barcode Technology

To enhance accuracy in tracking and inventory management, we integrate RFID and barcode technology. These systems facilitate quick and precise identification of products, minimizing errors in picking, packing, and shipping processes.

Automation and Robotics

Draco Logistics embraces automation and robotics to augment operational efficiency. Automated material handling systems, robotic picking solutions, and conveyor systems optimize tasks such as order fulfillment and reduce manual labor requirements.

Real-Time Monitoring and Analytics

Technology enables real-time monitoring and analytics of warehouse operations. Through IoT sensors and data analytics, we gain insights into factors like equipment performance, inventory levels, and overall warehouse efficiency, facilitating proactive decision-making.

Cloud-Based Solutions

Our use of cloud-based solutions enhances collaboration, accessibility, and scalability. Cloud technology ensures seamless integration with clients’ systems, facilitates real-time data exchange, and provides a secure platform for managing warehouse operations.

Pick-to-Light and Voice-Picking Systems

Draco Logistics implements pick-to-light and voice-picking systems for efficient order fulfillment. These technologies guide warehouse staff with visual or audio cues, reducing errors, minimizing training time, and enhancing the speed of order picking.

Predictive Analytics

Predictive analytics is harnessed to forecast demand, optimize inventory levels, and anticipate potential disruptions. By analyzing historical data and market trends, we proactively adjust warehouse logistics strategies to align with evolving business needs.

Mobile Technology for Accessibility

Mobile technology is integrated to enhance accessibility and flexibility. Warehouse staff utilizes mobile devices for tasks such as inventory checks, order processing, and communication, ensuring real-time connectivity and information exchange.

By leveraging cutting-edge technologies, we operate with precision, speed, and adaptability, ensuring that our clients benefit from state-of-the-art solutions that define the future of logistics.

Warehouse Safety and Compliance

Safety and compliance are paramount in warehouse operations, shaping the foundation for a secure and legally sound working environment. At Draco Logistics, we prioritize the well-being of our team, the integrity of our operations, and adherence to industry regulations. Here’s why safety and compliance are of utmost importance in our warehouse operations:

Employee Well-Being

The safety of our warehouse staff is a nonnegotiable priority. Implementing safety measures, providing proper training, and fostering a safety-conscious culture create an environment where employees can work confidently and without undue risks.

Legal Compliance

Adherence to local and international regulations is integral. Draco Logistics ensures that our warehouse operations comply with occupational health and safety standards, labor laws, and any industry-specific regulations to mitigate legal risks.

Reduction of Accidents and Incidents

Rigorous safety protocols minimize the occurrence of accidents and incidents. From implementing proper equipment usage guidelines to maintaining a clean and organized workspace, we actively work towards creating an environment that minimizes risks.

Training Programs

Continuous training programs are conducted to educate warehouse staff on safety procedures and compliance requirements. These programs cover topics such as proper lifting techniques, emergency response protocols, and the correct use of safety equipment.

Equipment Safety Measures

Draco Logistics implements stringent safety measures for equipment usage. Regular maintenance checks, safety inspections, and the provision of personal protective equipment (PPE) contribute to the safe operation of machinery and tools.

Emergency Response Preparedness

Being prepared for emergencies is crucial. Our warehouse operations are equipped with emergency response plans, including evacuation procedures, first aid stations, and fire safety measures, ensuring a swift and organized response in the event of unforeseen circumstances.

Ergonomic Workspaces

Designing ergonomic workspaces minimizes the risk of musculoskeletal injuries. Draco Logistics pays careful attention to the layout of workstations, the design of storage systems, and the selection of equipment to promote employee health and well-being.

Regular Audits and Inspections

Regular safety audits and inspections are conducted to assess and enhance warehouse safety. This proactive approach allows us to identify potential hazards, address compliance issues promptly, and continuously improve our safety protocols.

Draco Logistics recognizes that a commitment to safety and compliance is not just a legal requirement; it’s a fundamental part of our responsibility to our team and clients. By upholding the highest standards in safety and compliance, we create an environment where every member of our warehouse operations can work with confidence, and our clients can trust in the reliability and integrity of our logistics services.

Trends in Warehouse Logistics

The warehouse logistics industry is undergoing transformative changes, driven by technological advancements, evolving consumer expectations, and a focus on sustainability. Key trends shaping the landscape include:

Automation and Robotics

The increasing adoption of automation and robotics is revolutionizing warehouse operations. Automated material handling systems, robotic pickers, and autonomous vehicles are enhancing efficiency and reducing reliance on manual labor.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning technologies are optimizing tasks such as demand forecasting, route optimization, and inventory management. These intelligent systems contribute to data-driven decision-making and improved overall operational efficiency.

Real-Time Visibility

Demand for real-time visibility into warehouse operations is rising. Technologies such as IoT sensors, RFID, and advanced tracking systems provide instant insights, enabling better monitoring, quick problem resolution, and enhanced overall efficiency.

Sustainable Practices

Sustainability is a growing focus in warehouse logistics. From eco-friendly packaging materials to energ-yefficient facilities and green transportation options, warehouses are embracing practices that reduce environmental impact and align with corporate sustainability goals.

Omni-Channel Fulfillment

With the rise of ecommerce, warehouses are adapting to handle omnichannel fulfillment. The ability to seamlessly fulfill orders from various channels, including online platforms and brick-and-mortar stores, is a key trend in meeting diverse customer preferences.

Cloud-Based Solutions

Cloud-based solutions are gaining prominence, facilitating scalable and accessible warehouse management. These solutions enable real-time data exchange, collaboration, and enhanced flexibility in adapting to changing business needs.

Enhanced LastMile Delivery Solutions

Last-mile delivery solutions are evolving to meet the demand for faster and more convenient deliveries. Innovations such as autonomous vehicles, drones, and collaborative partnerships with local delivery services are becoming integral in enhancing last-mile logistics.

Focus on Talent Development

The industry is recognizing the importance of talent development. Training programs, upskilling initiatives, and creating a positive work environment are trends aimed at attracting and retaining skilled personnel in warehouse logistics.

These trends reflect the dynamic nature of warehouse logistics, with a continuous drive toward efficiency, sustainability, and adaptability. We stay at the forefront of these trends, ensuring that our warehouse operations are not just current but also futureready, providing our clients with cutting-edge solutions in an ever-evolving industry.

FAQ: Warehouse Logistics

Q: What is warehouse logistics, and why is it important in supply chain management?

A: Warehouse logistics involves the efficient planning, organizing, and controlling of the storage and movement of goods within a warehouse. It is crucial for optimizing supply chain operations, ensuring accurate inventory management, and facilitating timely order fulfillment.

Q: How does technology play a role in warehouse logistics?

A: Technology is integral to warehouse logistics, enhancing efficiency and accuracy. Warehouse Management Systems (WMS), RFID, automation, and real-time monitoring contribute to streamlined operations and data-driven decision-making.

Q: What are the key components of warehouse design and layout?

A: Warehouse design and layout include considerations for space utilization, workflow optimization, zoning for efficiency, adaptability to change, integration of technology, and adherence to safety standards.

Q: How does inventory management contribute to successful warehouse logistics?

A: Inventory management ensures accurate tracking, demand forecasting, and strategic placement of products. It plays a vital role in preventing overstock or stockout situations, optimizing storage, and facilitating efficient order fulfillment.

Q: What strategies are employed for order fulfillment in warehouse logistics?

A: Order fulfillment strategies include pick-and-pack optimization, batch and wave picking, technology-driven solutions, cross-docking, dynamic slotting, multi-channel fulfillment, continuous training, and last-mile delivery optimization.

Q: How does Draco Logistics prioritize safety and compliance in warehouse operations?

A: Draco Logistics prioritizes safety through employee well-being programs, legal compliance, reduction of accidents, continuous training, equipment safety measures, emergency response preparedness, ergonomic workspaces, and regular audits.

Q: What role does technology play in Draco Logistics’ warehouse operations?

A: Draco Logistics integrates technology such as WMS, RFID, barcode systems, automation, real-time monitoring, and cloud-based solutions to enhance operational efficiency, accuracy, and overall performance.

Q: What are the emerging trends in warehouse logistics?

A: Emerging trends in warehouse logistics include automation and robotics, AI and machine learning, real-time visibility, sustainable practices, omnichannel fulfillment, cloud-based solutions, enhanced last-mile delivery, and a focus on talent development.

Q: How can businesses benefit from outsourcing warehouse logistics?

A: Outsourcing warehouse logistics provides access to specialized expertise, cost efficiency, scalability, and the ability to focus on core business activities while ensuring efficient supply chain management.

Q: How can I explore warehouse logistics solutions with Draco Logistics?

A: Contact our team at Draco Logistics to discuss your specific requirements, explore customized solutions, and learn how our warehouse logistics services can optimize your supply chain.

Conclusion: Optimize Your Supply Chain

Ready to transform your warehouse operations? Draco’s commitment to safety, innovation, and client success mean you can trust us to optimize your supply chain with precision and efficiency.